JENA Float

Overview

JENA Float is a state-of-the-art, vertically profiling autonomous robot designed to collect critical oceanographic data from the surface down to great depths. Built as part of the GO-BGC (Global Ocean Biogeochemistry Array) initiative, JENA Float aims to help researchers monitor and understand the chemistry, biology, and physics of the global ocean in real time. Unlike traditional floats, JENA was engineered with real-world usability at its core. It features a next-generation PCB system, improving reliability, modularity, and serviceability in the field.

Advanced Buoyancy Engine

With a custom designed and manufactured buoyancy engine, JENA is able to control its vertical position within the water column. The motor driven piston is equipped with a high-prevision rotary encoder to adjust its density, allowing it to rise and sink at varying speeds autonomously. To do this, a PID controller is used to determine the ideal piston position location.

Compatible Communication

JENA Float is equipped with an external WiFi antenna that protrudes above the water's surface, allowing the robot to communicate via websockets to an access point located on shore. This AP can be connected to with any WiFi-enabled device, allowing for easy data visualization and control of the robot.

Pressure Sensors

The onboard pressure sensor can accurately measure the depth and pressure of the water column, providing critical data for scientific research and environmental monitoring. This can be accessed remotely via the web interface, allowing for real-time data analysis and decision-making.

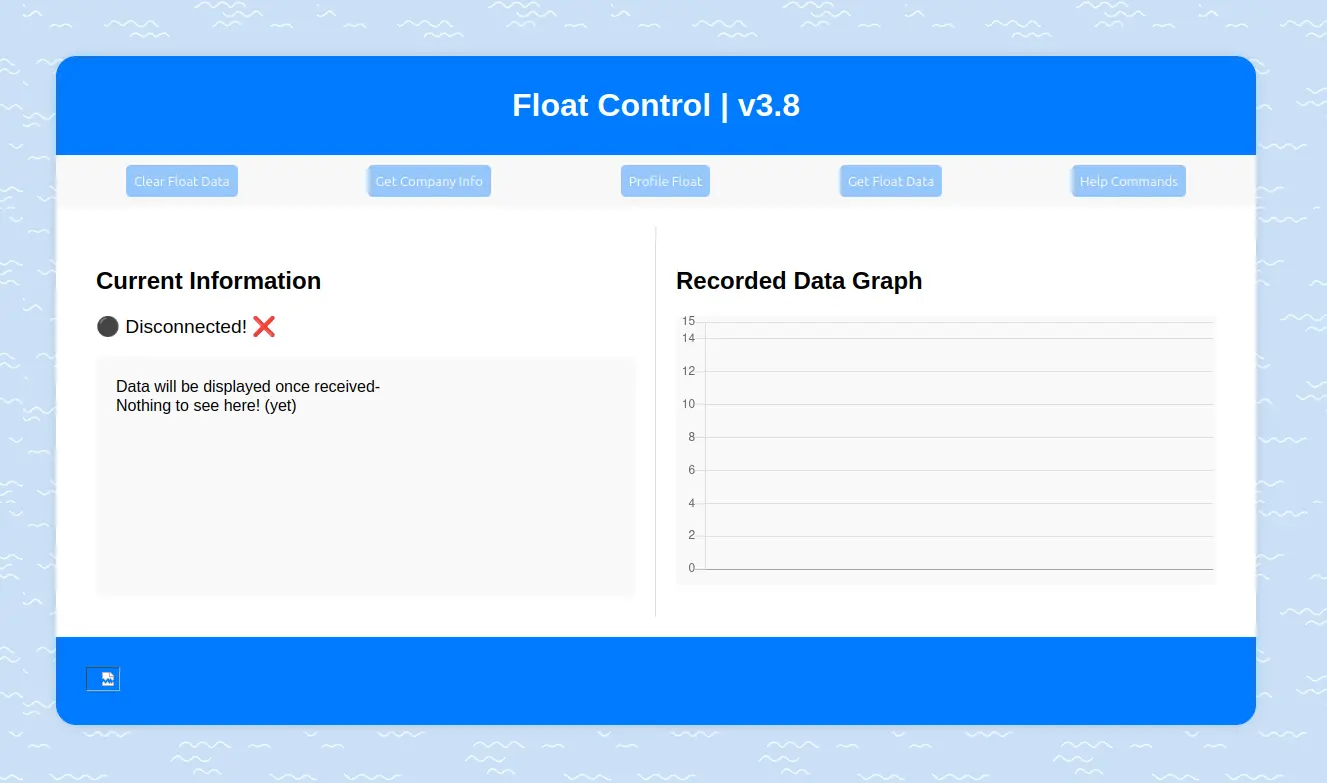

Advanced UI

The on-shore access point hosts a easy-to-use and intuitive web interface that allows users to remotely control the robot, view real-time data, and access advanced features such as remote monitoring and data analysis. The interface is hosted locally, removing the need for an internet connection.

3D Model

Technical Specifications

Buoyancy Engine and Structure

- Motor‑driven piston with integrated rotary encoder adjusts internal volume to vary density.

- Enables controlled ascent and descent at variable speeds.

- High piston‑shaft friction combined with a natural dead band below 30% motor speed prevents oscillations and overshoot.

- Mechanical design prioritizes stability and efficiency over raw speed, ensuring precise convergence to target depths.

Safety Systems

- Operates under vacuum rather than positive pressure, ensuring internal pressure never exceeds ambient hydrostatic pressure.

- Equipped with a 2.5 cm rubber stopper for passive pressure relief in the event of improper depressurization.

- Passive safety design eliminates risks associated with over‑pressurization and ensures reliable operation in diverse aquatic environments.

Antenna and Housing

- External antenna protrudes above the water surface for uninterrupted communication.

- Compact, field‑ready housing designed for durability and repeatable deployment.

Control System

- Rotary encoder provides precise piston position feedback.

- Closed‑loop PID controller determines optimal piston displacement.

- Proportional controller refines adjustments for fine depth regulation.

Sensors

- Depth and pressure sensors provide continuous feedback for profiling.

- Data sampled at fixed 5‑second intervals for consistent time‑indexed datasets.

Power and Reliability

- Electronics designed for low‑power operation during extended deployments.

- High‑friction piston and dead band characteristics reduce unnecessary motor activity, improving efficiency.

Command and Communication Protocol

- WiFi and WebSocket communication with a client laptop access point on shore.

- Supported commands:

- profile → Execute full vertical profile of the water column

- get_data → Return collected depth data array

- get_pressure → Return collected pressure data array

- set_target_depth → Define and hold a target depth during profiling

- set_hold_time → Specify dwell time at target depth for data collection

- break → Terminate communication and revert to standby mode

Data Handling

- Depth and pressure data returned as arrays.

- Each array element represents 5 seconds of float time.

- Each value corresponds to depth (m) or pressure (Pa).

- Structured format simplifies downstream analysis and integration into client workflows.

Control Logic

- Software integrates PID and proportional control loops with sensor feedback.

- Ensures smooth piston actuation and accurate depth convergence.

- Designed for robustness and repeatability in field conditions.