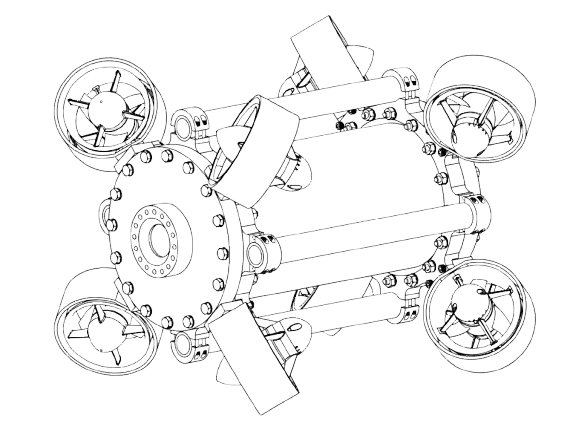

BOB ROV

BOB ROV IS CURRENTLY IN DEVELOPMENT. RESOURCES ON THIS PAGE ARE SUBJECT TO CHANGE

Design Purpose

BOB ROV was conceived as a general deep sea underwater platform, allowing operations at 500 meter depths. A modular design will allow BOB ROV to be outfitted with tools for roles such as exploration, sea bed sampling, infrastructure installation and repair.

Technical Specifications

Enclosure

- Hardware specifications coming soon...

Electronics Information

- Electronics specifications coming soon...

Code Documentation

- Work in progress code documentation is available on our Documentation Website

Software Information

- Software specifications coming soon...